Customer Service

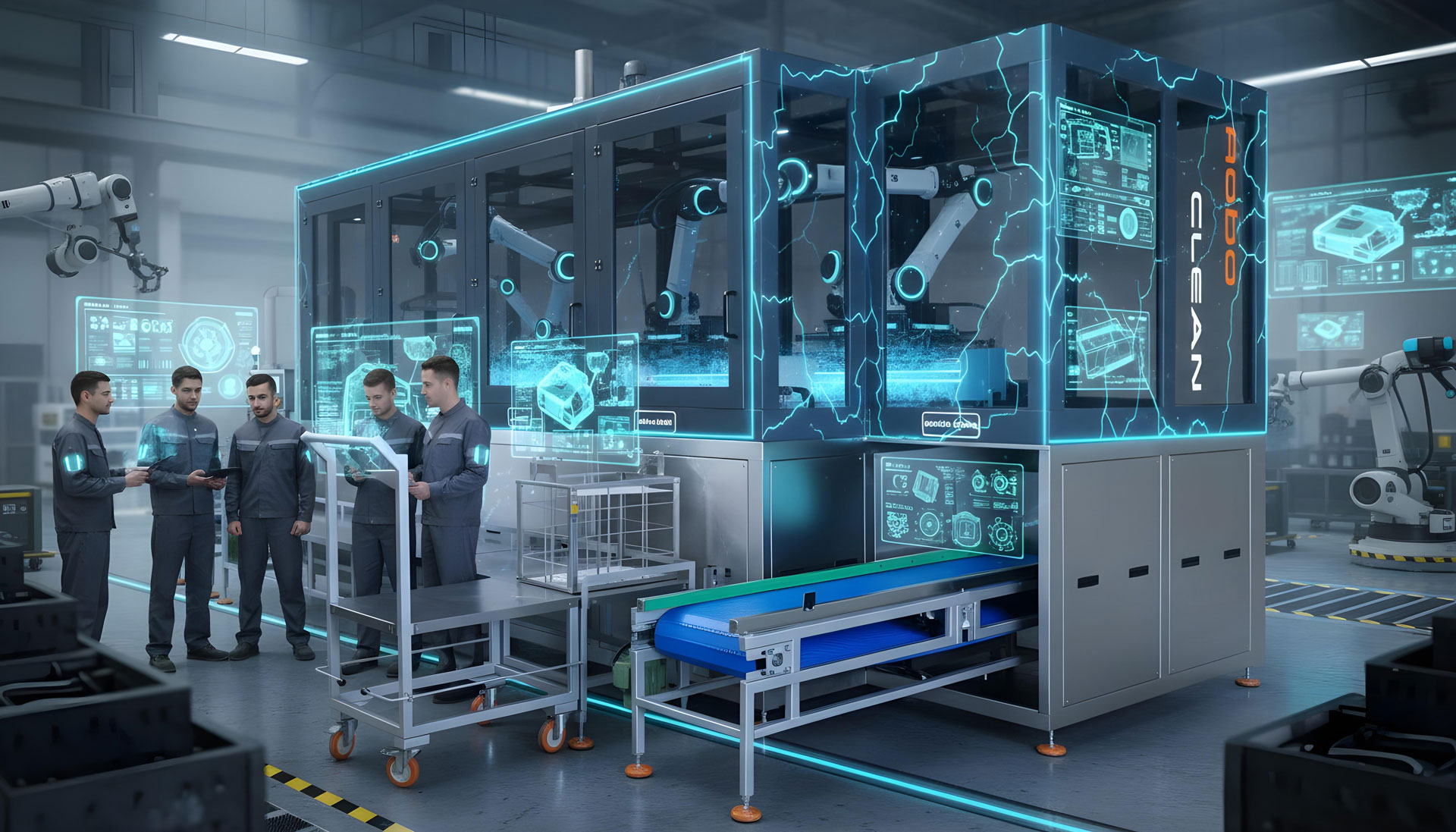

Reliability, technology, and sustainability

in industrial cleaning.

PRODUCT GROUPS

We are the national and international

market leader in our field.

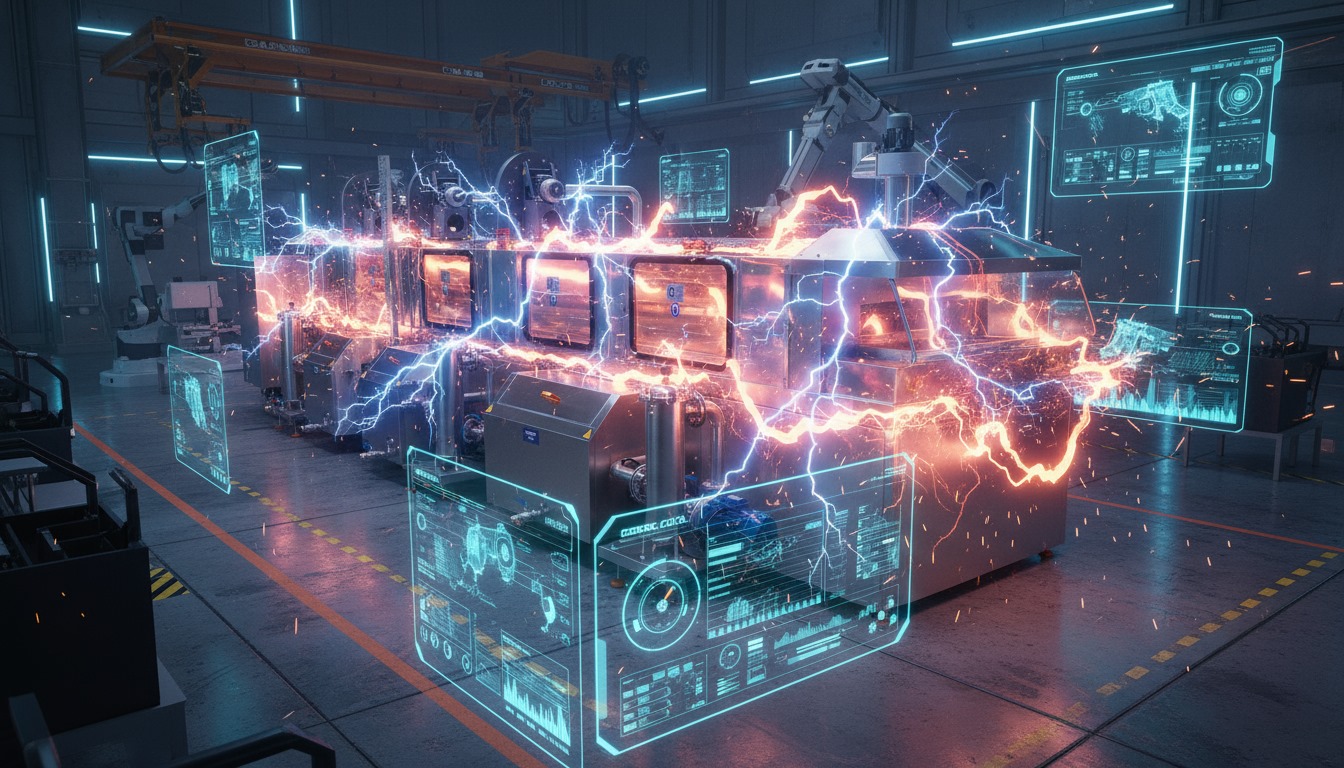

KSP MACHINE

Tailor-made solutions for every need,

strong advantages at every step.

SOLUTIONS & ADVANTAGES

Customized solutions for different industries,

high performance in every field.

INDUSTRIES

The latest news, fairs, and events

from KSP in one place.

MEDIA CENTER

Reach us anytime,

get closer to our solutions.

CONTACT